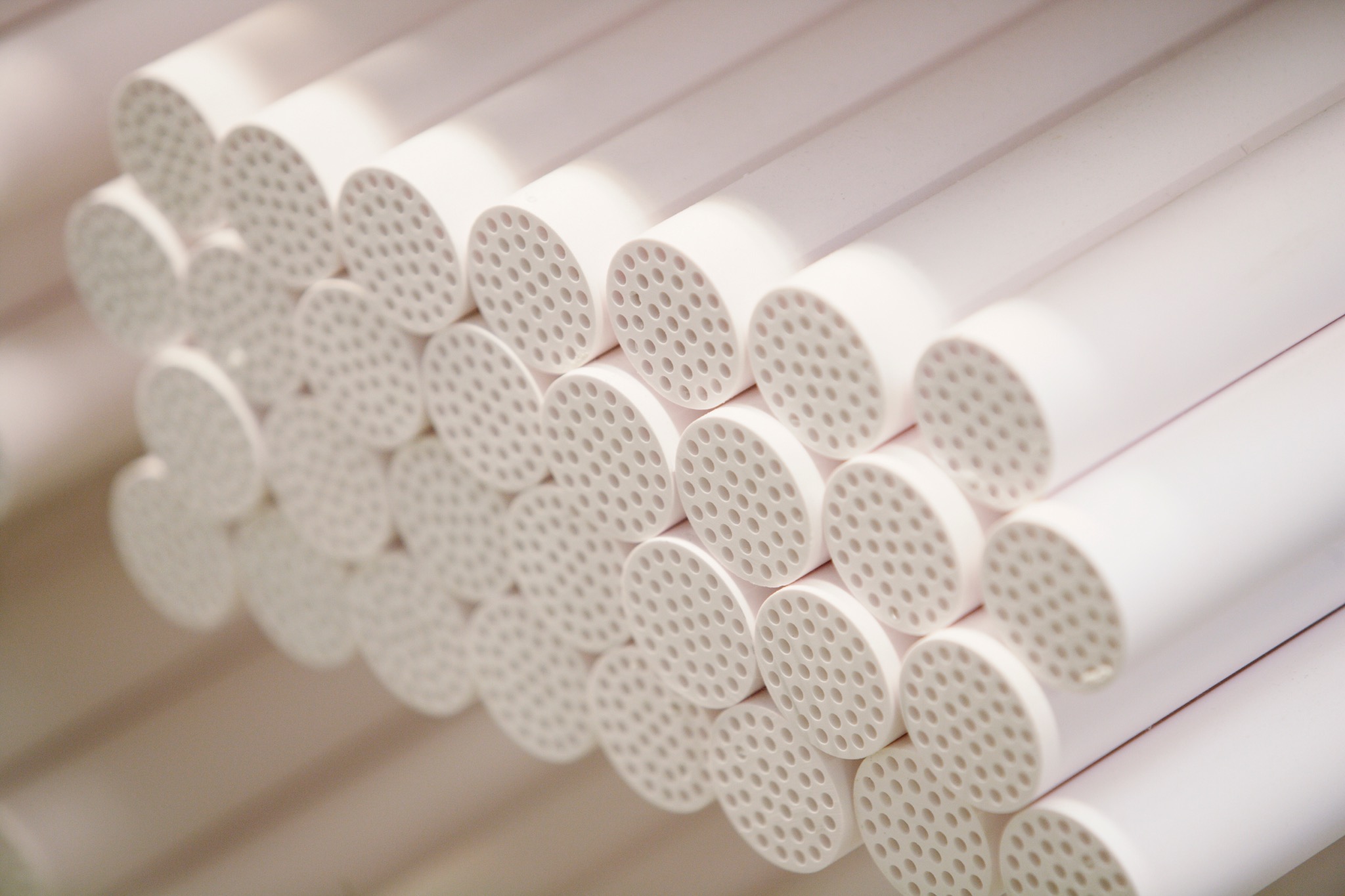

The HIREC® process applies ultra-filtration technology, where special types of ceramic membranes are used, allowing an uninterrupted filtration process without the necessity of regular membrane replacements. The spent wiping solution passes through the tubular filter elements with very fine pores, the so-called membrane layer. Only the pure wiping solution can permeate through these layers, while ink particles and other impurities remain in the residue.

As HIREC® technology is adapted to the continuously-rising demands of the banknote industry, a complete redesign was launched a few years ago. The changes have led to a significant reduction in energy consumption and an overall reduction of the unit size, thus lowering both ecological and physical footprint. However, over the years the application of best available components including membranes, pumps and electronic measurement equipment has led to superior performance and satisfied customers.

Every HIREC® plant comes as a fully automatic and self-protecting system which is controlled via PC or touch panel. Sufficient buffer capacity as well as redundant concepts allow maximum flexibility and secure continuous supply of wiping solution to the printing machines.